Smart Brine Viewer

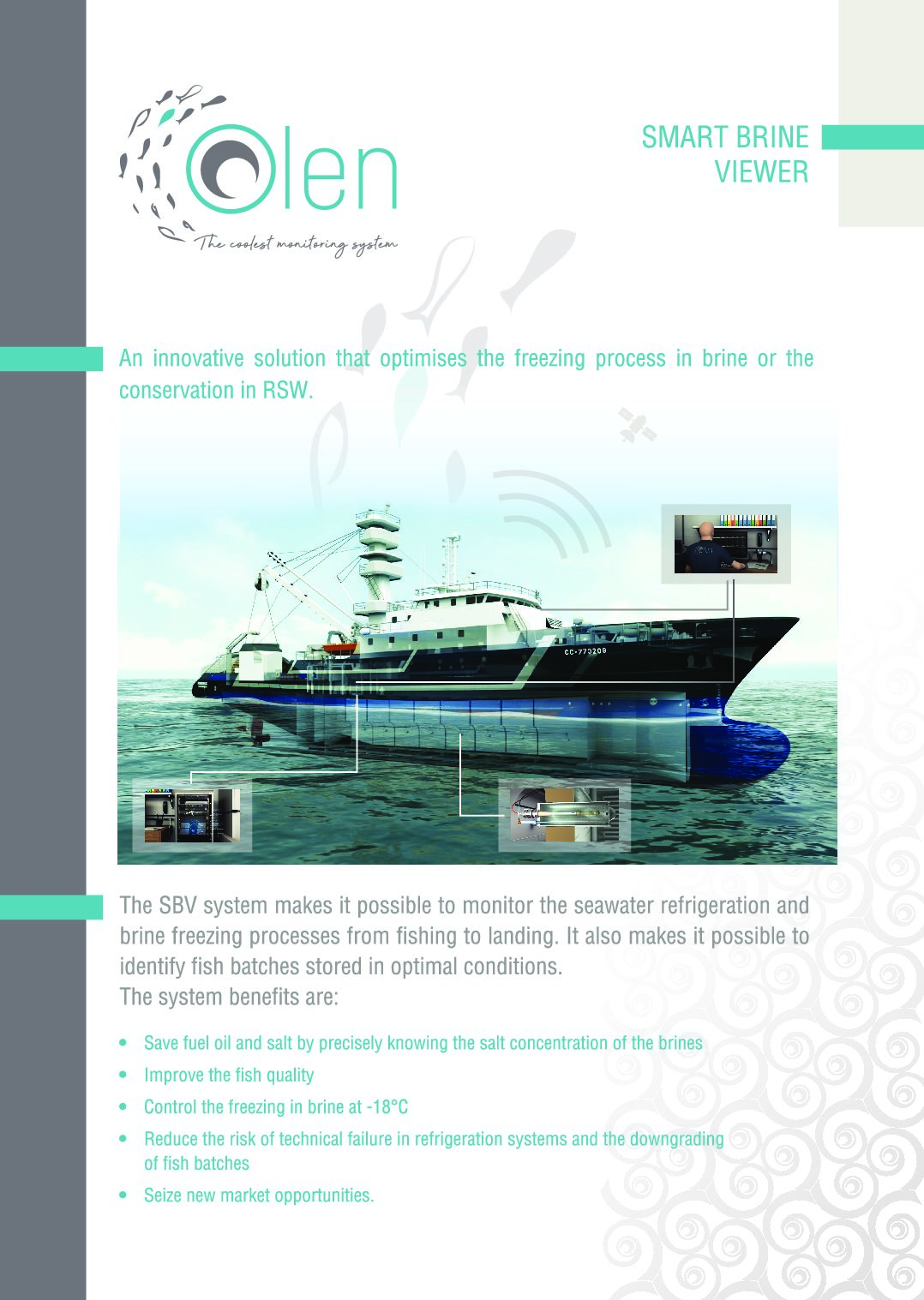

An innovative solution that optimises the freezing process in brine or the conservation in RSW.

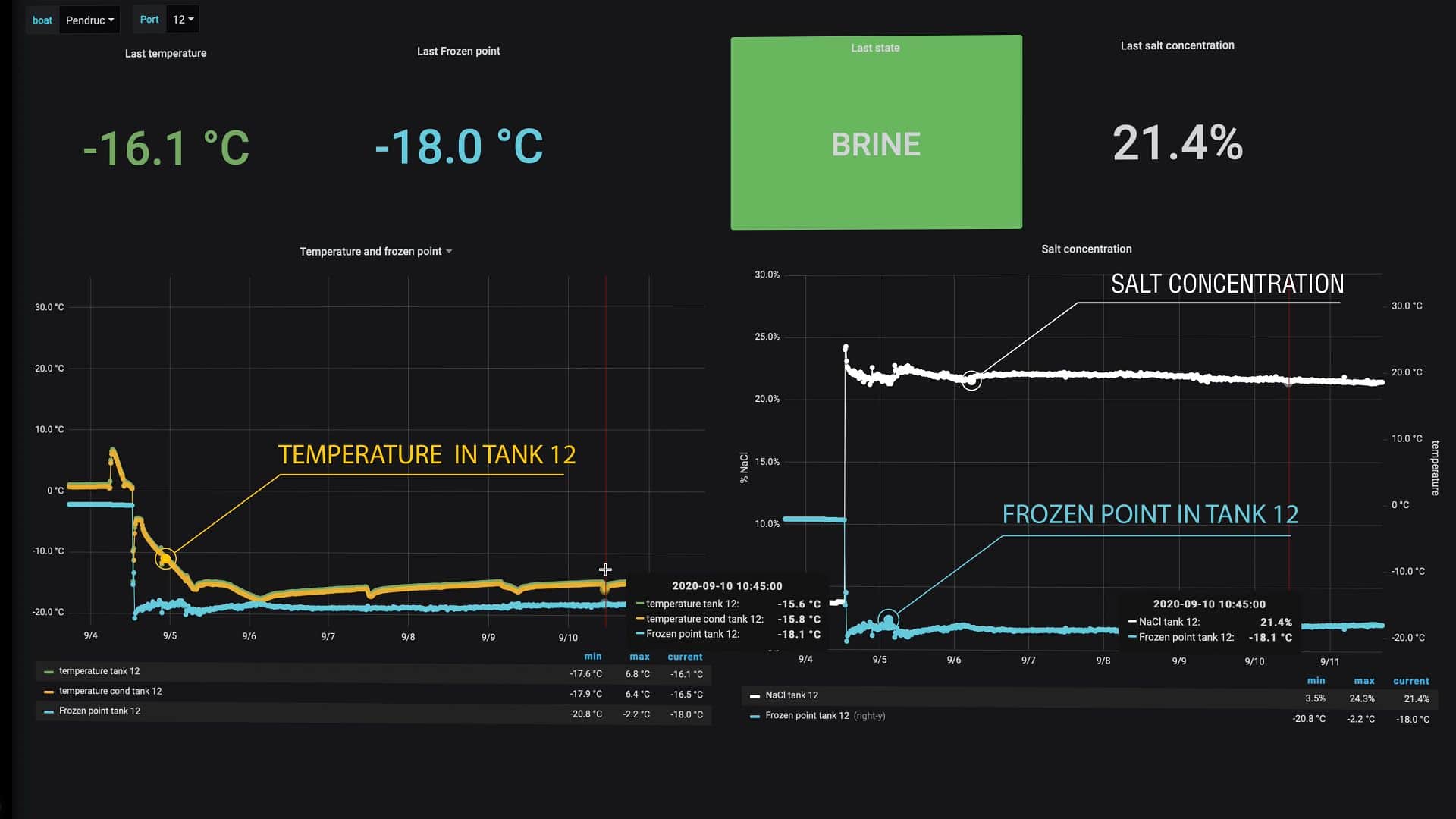

The data supervision is carried out through the IHM SBV software program, which offers:

An overview of all the tanks that shows the condition of each individual tank: empty, in sea water, in brine; the temperature, the mass concentration of salt and the liquid freezing point.

A specific view per tank detailing the evolution of the temperature, the mass concentration of the liquid and the freezing point of the liquid in graphical form.

The SBV system makes it possible to monitor the seawater refrigeration and brine freezing processes from fishing to landing. It also makes it possible to identify fish batches stored in optimal conditions.

The system benefits are:

Save fuel oil and salt by precisely knowing the salt concentration of the brines

Save fuel oil and salt by precisely knowing the salt concentration of the brines Improve the fish quality

Improve the fish quality Control the freezing in brine

Control the freezing in brine Reduce the risk of technical failure in refrigeration systems and the downgrading of fish batches

Reduce the risk of technical failure in refrigeration systems and the downgrading of fish batches Seize new market opportunities

Seize new market opportunities

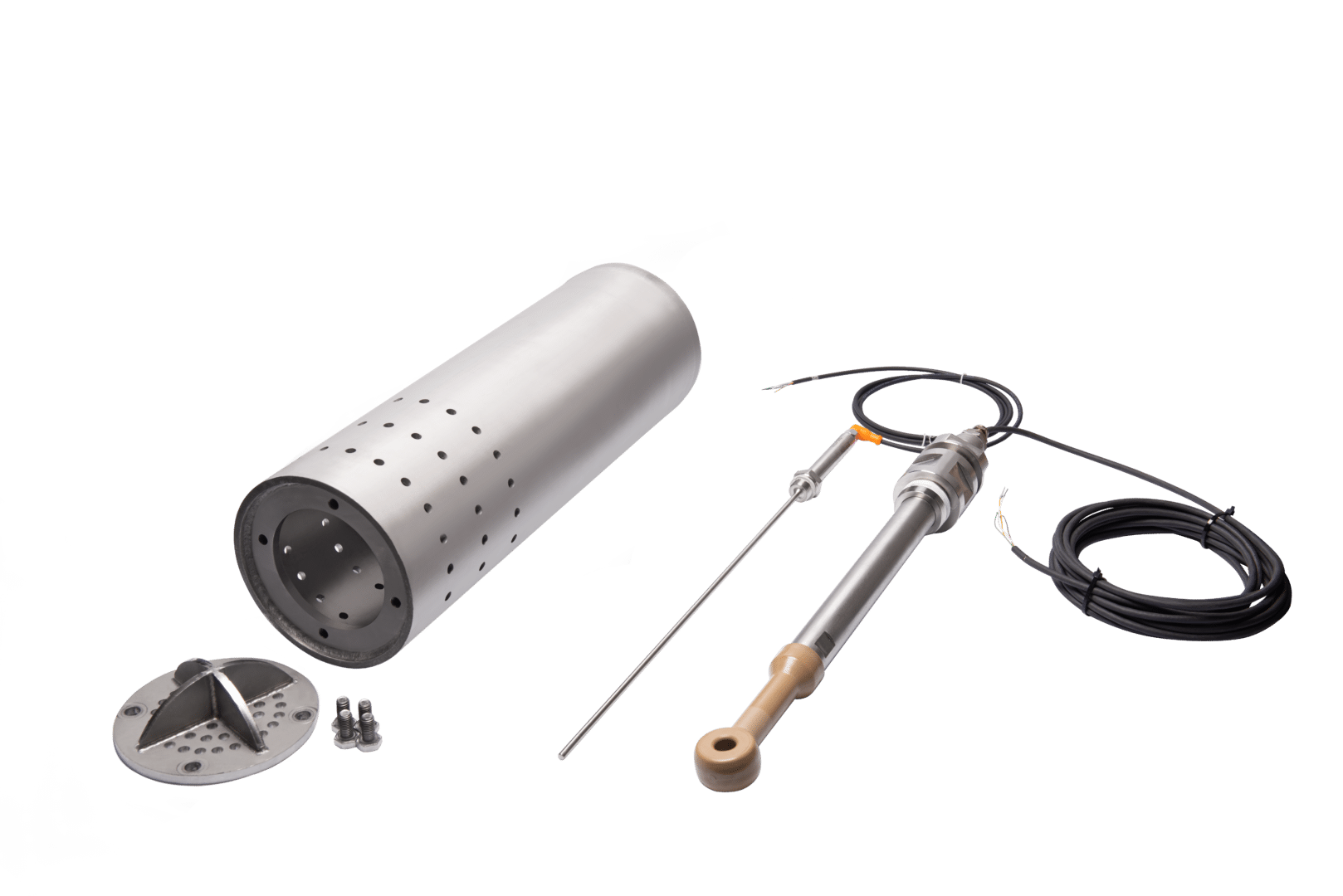

Temperature and conductivity probes of the SBV system

![]()

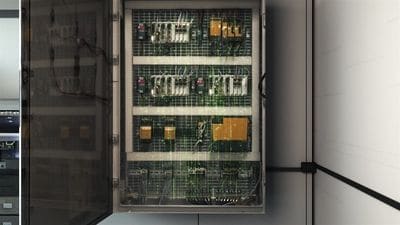

Industrial cabinet, data centre and thin client

![]()

SBV Algorithm and IHM software

![]()

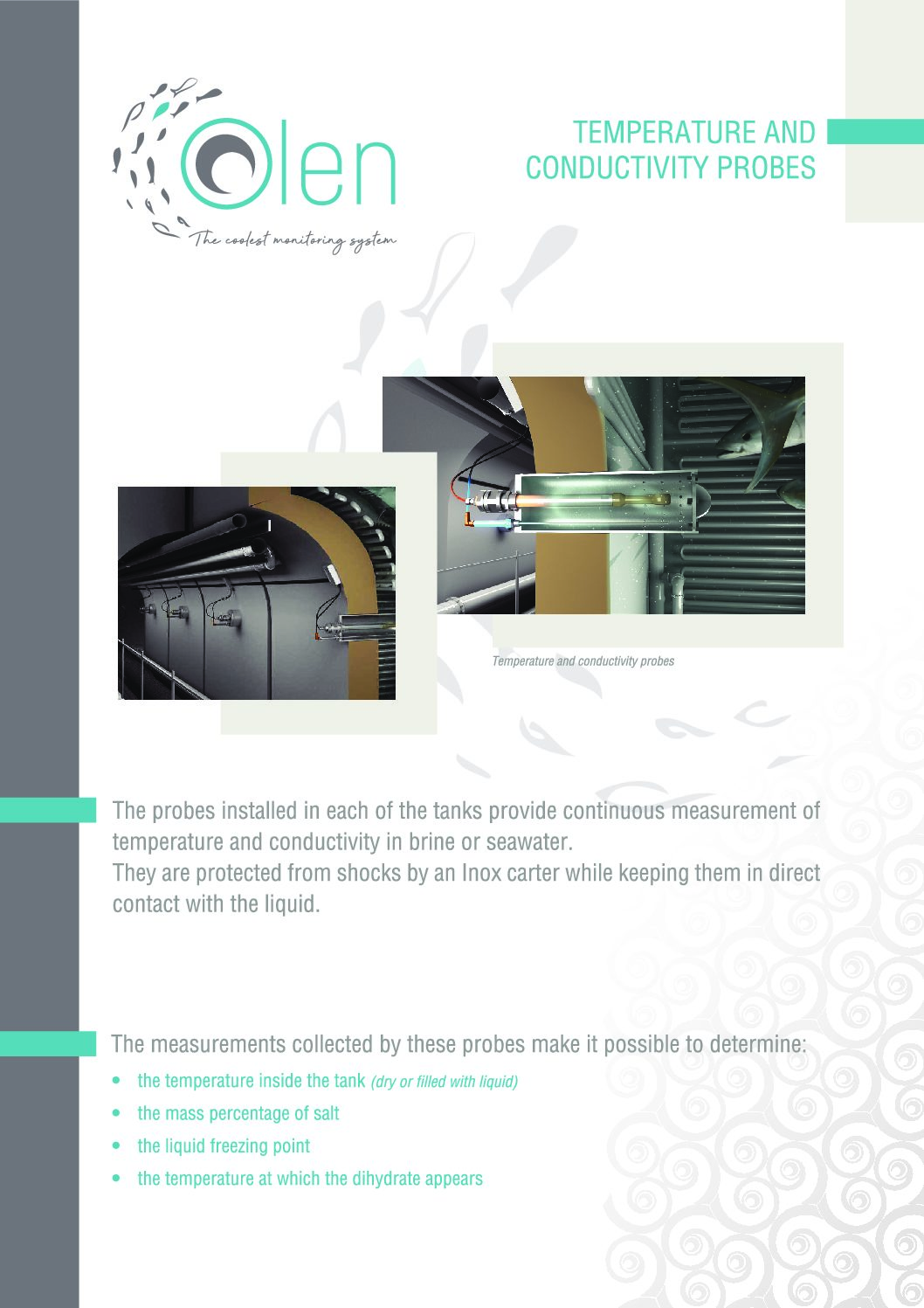

Temperature and conductivity probes of the SBV system

![]()

![]()

![]()

The probes installed in each of the tanks provide continuous measurement of temperature and conductivity in brine or seawater. They are protected from shocks by an Stainless steel carter while keeping them in direct contact with the liquid.

The measurements collected by these probes make it possible to determine:

- the temperature inside the tank (dry or filled with liquid)

- the liquid mass concentration of salt

- the liquid freezing point

- the temperature at which the dihydrate appears

These probes meet high-precision metrology standards and have been selected to withstand the restrictive environment of the vessels and the freezing and refrigeration processes.

Industrial cabinet, data centre and thin client

![]()

![]()

![]()

Data collection and processing, supervision of the freezing process

Industrial cabinet

The network of cables coming from the different tanks of the vessel converges towards the industrial cabinet, designed to collect the continuous flow of information, while avoiding any disruption, damage or signal break. This industrial quality cabinet can accommodate data from sensors up to 24 tanks.

Thin client and touch screen

Thanks to the thin client and the touch screen installed in the laptop, the operator supervises the temperature and salinity parameters of the different tanks of the vessel and their evolution during the tide in real time.

Data centre

Then, the information flow is sent to the data center in which the data are time-stamped, processed and protected by encryption. Server and data security are ensured by the system architecture, redundancy and protection against electric shocks. The information can be accessed from any ethernet network point on the vessel by installing the software on laptops at different places on the ship (gateway, cabin…). Optional: Regular satellite exports allow the shipowner to see the freezing and/or refrigeration parameters of his fish loads by vessel and for his entire flotilla..

SBV Algorithm and IHM software

![]()

![]()

![]()

Innovative development resulting from the R&D carried out by Olen

Algorithm

Olen’s metrological research was triggered by the fact that no system was able to display the salinity of brine or seawater in the refrigeration and freezing processes used in the fishing industry. This is how a specific algorithm for processing data from SBV sensors has been developed.

This algorithm determines the salinity of the brine at positive and negative temperatures and at each stage of brine ageing. It also defines the freezing point of the brine, an essential information in the cold descent process to determine a target temperature and avoid any risk of damage on the on-board refrigeration systems.

Software

The IHM SBV software has been specifically developed to meet the needs of the technicians involved in the cold control inside the ship’s tanks and to make full use of SBV technology.

Thanks to its interfaces, the technician can monitor the temperature in each tank, the mass concentration of salt in the brine or seawater, as well as the freezing point value of the liquid.

You can download our product information sheets:

Bureau Veritas evaluates the proper functioning of the “Smart Brine Viewer” system developed by Olen measuring data related to the temperature and salinity of the fish caught.